Located approximately 160km south-east of Halls Creek in northern Western Australia, the Browns Range project is the flagship project of Australian mining company Northern Minerals.

The company focuses on the production of the heavy rare earth element dysprosium, which is used in the manufacturing of permanent magnets and in electric motors and wind turbines.

Definitive feasibility study for the Browns Range project was completed in March 2015, and the Western Australian Department of Mines and Petroleum (DMP) approved the project plan in August 2015.

When completed, the project will be Australia’s only heavy rare earth project and the first significant dysprosium producer outside of China. It is expected to have a mine life of 11 years.

Three-stage development of Browns Range mine

The project is proposed to be developed in three development stages, namely the pilot plant stage, development to bankable feasibility study level, and a full-scale operation.

The $56m pilot plant project involves the construction of a three-year, 60,000tpa plant to produce 49,000kg dysprosium, in 590,000kg total rare earth oxide (TREO) a year. The pilot plant project is expected to start production of RE carbonate in the first quarter of 2018.

The second stage will involve the development of the mine from trial phase to bankable feasibility study level based on the results of the detailed feasibility study (DFS). It will focus on minimising the mining costs, improving productivity, producing a premium product, and increasing the ore reserves.

The final stage involves bringing the project to full-scale production based on the outcomes of the first two stages and the DFS.

The third stage will include the extraction of 585,000tpa of ore at 0.66% TREO resulting in the production of 279,000kg of dysprosium contained in 3.09 million kilos of TREO a year.

Geology and mineralisation

Spread over 3,595km², the Browns Range rare earths project is centred on the Browns Range Dome located within both Western Australia (WA) and the Northern Territory (NT). The project comprises deposits and prospects filled with high-value dysprosium and other HREs, hosted in xenotime mineralisation.

Northern Minerals has 100% ownership and marketing rights for all tenements covering the Browns Range Dome except three, which are held under a joint venture (JV) with Toro Energy.

The project is located on the western portion of the paleoproterozoic Browns Range Dome. The deposits are characterised as breccia-hosted hydrothermal systems with huge amounts of rare earth phosphate mineral xenotime mineralisation.

The Wolverine deposit mineralisation comprises 89% of the rare earths and is located below a cover of transported clays, sand and gravels.

Reserves

The proven and probable reserves at Browns Range as of March 2015 are estimated to be 3.8Mt containing approximately 2,294t of dysprosium and 26,375t of TREO.

Mining at Browns Range

Conventional mining methods including both open-cut and underground will be applied at the Browns range project. Open-pit mining will be performed at the Wolverine, Gambit, Gambit West, Banshee, and Area 5 deposits, while the Wolverine and the Gambit West deposits have a scope for underground development.

The Wolverine, Gambit, Gambit West and Area 5 open-pit deposits will be mined concurrently during the first two years of the mining, while a second stage of Wolverine pit along with the Banshee deposit will be mined in a later phase of open-cut mining.

Access to the Wolverine underground mine will be through a portal within a small box-cut commencing the decline from surface, while the Gambit West mine will be accessed through a portal from near the base of the Gambit West pit.

Longitudinal open stoping method of mining, followed by extraction backfill, will be applied at the Wolverine underground mine. The Gambit West underground mine will use bench and fill technique with backfill using run-of-mine waste.

Processing of ore from Browns Range

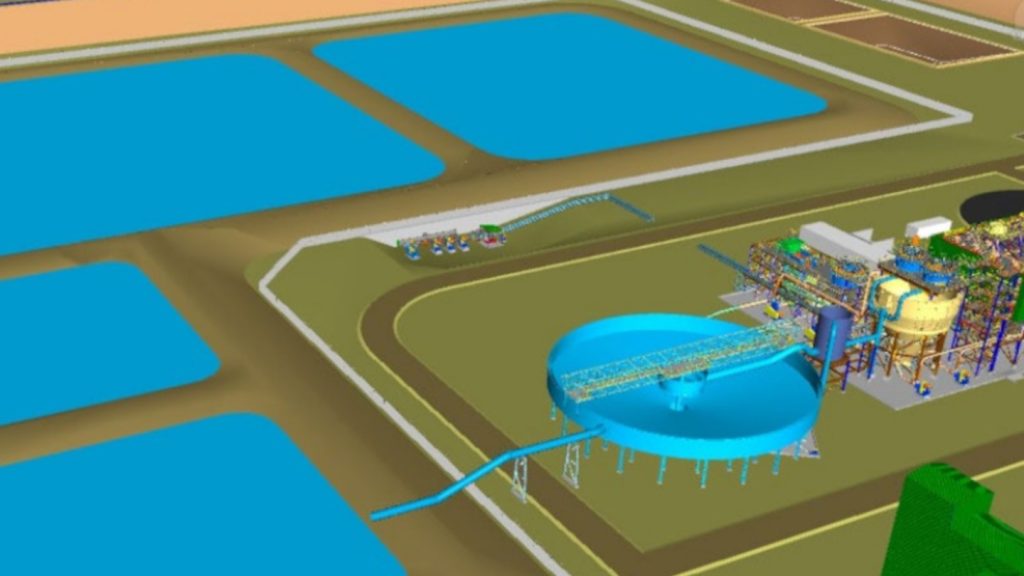

The run-of-mine (ROM) ore will be transported to the processing plant, which will comprise two circuits – beneficiation plant circuit and the hydrometallurgical plant circuit.

The beneficiation plant will comprise a crushing circuit and a wet high-gradient magnetic separation and flotation circuit.

The ROM ore will be crushed and grinded to a required size of 80% passing 63µm in the crushing circuit. The ground ore will then be fed to a wet high-gradient magnetic separator (WHGMS) to produce a magnetic concentrate rich in xenotime and iron oxide.

The xenotime-rich magnetic concentrate will then pass through a flotation circuit to produce TREO flotation concentrate, which will be thickened and filtered prior to being fed into the hydrometallurgical plant.

The hydrometallurgical plant will use sulphation bake method, followed by water leach, purification, precipitation to produce a mixed RE carbonate concentrate. The concentrate will then be washed, thickened, filtered and dried to produce a high-purity dysprosium-rich mixed rare earth carbonate.

The final RE carbonate product will be packed in bags in 20t shipping containers and transported by road to the Port of Wyndham for export.

Offtake from Browns Range project

Northern Minerals entered a sales agreement with Lianyugang Zeyu New Materials Sales (JFMAG) for the offtake of entire HRE product produced at the pilot plant in April 2017.

Northern earlier signed a memorandum of understanding (MoU) with Jien Mining in relation to product offtake from the Browns Range project in August 2015.

Under a non-binding MoU signed in December 2012, Japan’s Sumitomo Corporation will purchase up to 1,500t of TREO a year produced at Browns Range for a period of five years from the start of commercial production.

Contractors involved

Sinosteel MECC was engaged as the engineering, procurement, and construction (EPC) contractor for the Browns Range pilot plant project in December 2016. Sinosteel sub-contracted the Beijing unit of Worley Parsons to undertake the detailed design of the pilot plant.

MACA was awarded the $6m mining contract for the pilot phase of Browns range mine. DRA Global (DRA) was contracted to provide detailed engineering design for the 60,000tpa Browns Range pilot plant, while Entech is responsible for the detailed mine planning.

Financing for Browns Range mine development

The HREO project is being financed through a combination of debt, equity, a $10m sales prepayment, and deferred payment terms from Sinosteel MECC.

Sinosteel agreed to postpone 20% of the EPC contract costs for a period of 24 months from completion, with the option to convert into equity.

Northern Minerals raised $10m through a private share placement under an underwriting agreement with AMC Wanhai Securities, a company based in Hong Kong.