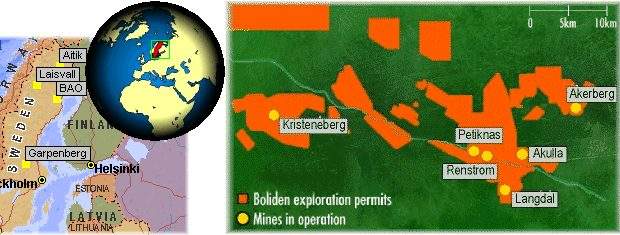

In 1924, the Holmtjarn gold deposit was discovered at Boliden, near Skelleftea in northern Sweden. Soon after, the Boliden Mining Company was formed. Although this mine shut in 1967, the concentrator has continued to treat ores from other Boliden mines in the area (40 over the years), and to supply the Ronnskär smelter which Boliden opened at Skelleftehamn on the Baltic coast in 1930. Today, the Maurliden open pit and the Kristineberg, Petiknas and Renström underground mines, plus the Boliden concentrator, are referred to as the company’s Boliden Area Operations (BAO).

Since January 2004, when Boliden AB and Outokumpu Oy consolidated their zinc and copper mining and smelting interests, the operations have been owned by New Boliden, which is now the world’s fourth largest zinc-mining company as well as a leading metals-smelting firm and achieved record results in 2005.

GEOLOGY AND RESERVES

In the Skelleftea field, mineralisation is found in precambrian supracrustal rocks that have been structurally deformed by granite intrusions. Typically, complex sulphide deposits occur at the boundary between volcanic and sedimentary rocks, often at considerable depth.

Consequently, despite the area having been explored for more than 70 years, deposits continue to be identified. The company continues to allocated funding for exploration here, aiming to define sufficient reserves for mining until beyond 2015. This on-going effort has most recently located the high-grade zinc-silver K-zinc zone and copper-gold-zinc mineralisation in the J-zone at Kristineberg. Previous finds include the Simon and Renström Deep zones at Renström, and the Maurliden copper-zinc orebody, now being mined as an open pit.

Independently, North Atlantic Natural Resources (now Lundin Mining) discovered the Storliden copper-zinc deposit, near Malå, and started shipping ore to the Boliden concentrator in mid-2002.

As of January 2006, total BAO proven polymetallic reserves were 150,000t of ore grading 8.9% zinc, 1.0% lead, 0.4% copper, 1.4g/t gold and 151g/t silver. Probable sulphide reserves totalled 2.77Mt at 6.6% zinc. In addition, Kristineberg had proven gold ore reserves of 30,000t grading 7.1g/t Au, 4g/t Ag and 0.9% Cu. Measured polymetallic resources totalled 360,000t at 3.2% zinc, 1.7% copper 7.1g/t gold and 69g/t silver. Indicated and inferred polymetallic resources totalled 7.4Mt while indicated and inferred gold resources at Åkulla East and Kristineberg totalled 2.4Mt.

MINING

The polymetallic ore supplied to the Boliden concentrator in 2005 came from the Maurliden open pit, which started up in 2000, and the three established underground mines.

The underground mines are mainly worked by various cut-and-fill techniques, with all activities thoroughly mechanised. Open cuts are worked by contractors. The main recent investment has been the connection of Petiknäs to the Renström shaft by rail haulage on the 800m level.

ORE PROCESSING

The concentrator was commissioned in 1953 and rebuilt in 1989–91, increasing capacity to 1.5Mt/y and improving performance. The redesign introduced autogenous grinding, large flotation cells, pressure filtration and a process information system, with Nordic manufacturers supplying most of the equipment. New flotation and process control technologies have since been introduced and an SEK100m gold leaching plant was commissioned in 2001 to treat gold-rich ore, mainly that from the Einarsson zone at Kristineberg, discovered in 2000. Processing Storliden ore has necessitated some further circuit optimisations, and the capacity is now 1.6Mt/y of ore.

Concentrates are railed to the nearby Ronnskär smelter (see also the Aitik mine profile).

PRODUCTION

The Boliden concentrator maintained production levels in 2005. The 1.78Mt of ore treated graded 6.1% zinc, 1.5% copper, 0.6% lead plus 2.1g/t gold and 78g/t silver. Yields were 161,613t of 54% zinc concentrate, 75,542t of 27.5% copper concentrate and 10,516t of 28.9% lead concentrate, plus 347t of precious-metals concentrate and 2,480kg of gold doré metal. Contained metal-in-concentrate outputs were 87,276t of zinc, 20,746t of copper, 87,212kg of silver and 2,428kg of gold.