The Bissett Creek graphite mine, owned by Northern Graphite, is located between the cities of Ottawa and North Bay in Ontario, Canada, approximately 15km from the Trans-Canada pipeline and highway.

A mining lease for the graphite project was granted in August 2013. Construction is anticipated to commence late 2014 and production is expected to start by the end of 2015.

The mine is expected to produce a yearly average of 20,800t of graphite concentrate during its 28-year lifetime, while the production over the first ten years of operation is expected to be 38,000t. The estimated capital cost of the project is $102.9m (including $9.4m for contingency).

Bissett Creek mine details

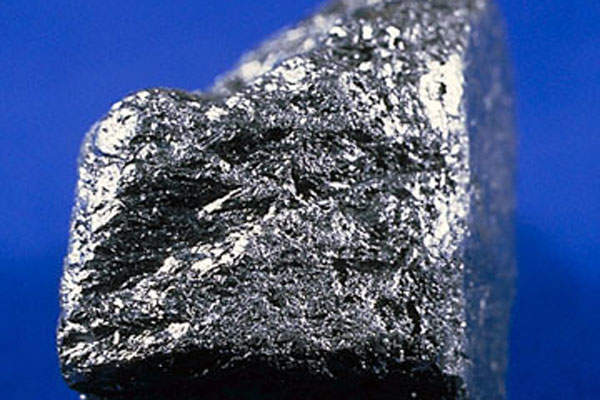

The Bissett Creek project is part of the Ontario segment of the Central Gneiss Belt of the Grenville structural province. The deposit consists of middle Precambrian meta-sediments and is classified as disseminated flake graphite, with most of the graphite tending to be associated with biotite.

The graphite mineralisation at Bissett Creek is characterised by homogeneously distributed graphite flakes within the biotite schists filled with amphibole, clinopyroxene, chlorite, carbonate and graphite.

As of September 2013, the probable reserves were estimated to be 28.3Mt grading at 2.06% Cg (graphitic carbon), whereas the measured and indicated resources were estimated to be 69.8Mt at a grade of 1.74% Cgas as of May 2013, and inferred resources were 24Mt grading at 1.65% Cg.

Mining and processing at Bissett Creek

The open-pit mine will be mined using conventional loading-hauling methods and the ore will be transported to the processing plant by trucks. The mining fleet will comprise two front-end loaders, four 71t capacity haul trucks, a Cat 336E backhoe, two Cat D7E class dozers and a Cat 14M grader.

The Eagle Gold Project is located within the Mayo mining district of Yukon Territory, Canada.

The processing plant will initially have a capacity of 1Mtpa, which will be increased to 2Mtpa during the third year of operation. The run-of-mine mill feed will be crushed in a mobile jaw crusher and conveyed to a stockpile. The crushed mill feed will then be fed to a 30kW SAG mill feed conveyor via two apron feeders.

The graphite concentrate from the cleaners will be thickened in a high-rate thickener, before being filtered and dried. This will then be fed to graphite bins, where the graphite flakes will be recovered and bagged in different storage capacities.

Infrastructure facilities at the graphite mine

The mine will be accessed by an upgraded road, while the haul road will allow the haulage of mill feed to the processing facility. The tailings management facilities and the pumping stations will be accessed via service roads.

A 5MW natural gas-fired power plant will be installed to produce power for the plant’s operation. Compressed natural gas for the power plant will be supplied from the main Trans-Canada line, which is located approximately 15km away.

Two separate storage facilities will be maintained to store the generated tailings. Non-acid tailings will be stored at the non-deleterious tailings management facility, while acid generating tailings will be stored at the sulphides tailings management facility.

The mine will also consist of support buildings and infrastructure facilities, including water pumping stations and a treatment facility.

Key players in the mine development

PES-BECMA, a joint venture of Porcupine Engineering Services and BECMA, was awarded the detailed engineering and design contract for the graphite mine. The scope of the $3.5m contract includes engineering and design of the 2,500t a day processing facility, as well as the associated infrastructure.

Cassier Engineering will provide a bagging system for the Bissett Creek project.