Located approximately 15km from the Cap Verga peninsula, Guinea, the Bel Air bauxite mine is being developed by Alufer Mining. The feasibility study for the bauxite mine was completed in April 2013 and environmental certification was received from the Ministry of Environment in June 2013.

The Government of Guinea declared the project as a ‘Project of National Interest’ in December 2014. Alufer signed a Mining Convention with the government in February 2016, which was ratified by the Guinean Parliament in June 2016 and granted the Presidential Decree in July 2016.

Construction commenced in January 2017 and is expected to be completed in approximately 18.5 months. First bauxite production from the project is scheduled for the second quarter of 2018, while the first ore shipment is expected to be made in the third quarter of 2018.

Bel Air is expected to have an initial production rate of 5.5 million tonnes per annum (Mtpa) with a potential to reach 10Mtpa.

The project is expected to create approximately 3,500 direct and indirect jobs and is anticipated to have a mine life of approximately 15 years.

Bel Air bauxite mine reserves

The Bel Air mine has JORC-compliant resources of more than 146 million tonnes (Mt) of high-grade tri-hydrate bauxite.

Bauxite mineralisation at Bel Air mine

Bauxite found at the Guinean mine is mainly high-quality trihydrate bauxite with very low reactive silica. It can be processed as full or partial feedstock in low and high-temperature refineries or for sweetening process.

The bauxite at Bel Air has been classified into three types namely DSO bauxite, ferruginous bauxite and lateritic (or clayed) bauxite. Ferruginous and lateritic bauxite can be converted into export products through beneficiation process followed by washing and screening.

The quality of bauxite at Bel Air is quite identical to CBG and Kindia, which are the best quality materials available in the market.

Mining and processing at Bel Air

Surface mining approach will be applied to mine the Bel Air bauxite mine. Direct shipping ore will be mined from a total of six open pits with a minimum of two areas to be in continuous operation to maintain production flexibility.

Mining operations are expected to commence and focus on pits 2 and 5 in the second and third years of development. Pits 3, 4 and 6 will be mined from year four to the ninth, while pit 1 will be mined in the final four years.

The pits will be mined sequentially using the Wirtgen surface mining technology. Surface miners will mine and crush the ore and load onto 40m³ side tipping trucks for delivery to the run-of-mine (ROM) bin. Ore will be hauled by trucks to the proposed export facility located 15km from the mine site at Cap Verga.

Transhipment of bauxite

The export facility includes a 1.4km-long rubble mound causeway, conveyor, berth and barge loader. DSO ore will be loaded on the causeway conveyor by a stockpile reclaim conveyor to the transhipment zone (TSZ) located approximately 32km from the shore.

The barges will load the bauxite at a barge berth located at the end of the causeway and transfer onto an ocean-going vessel (OGV) for export.

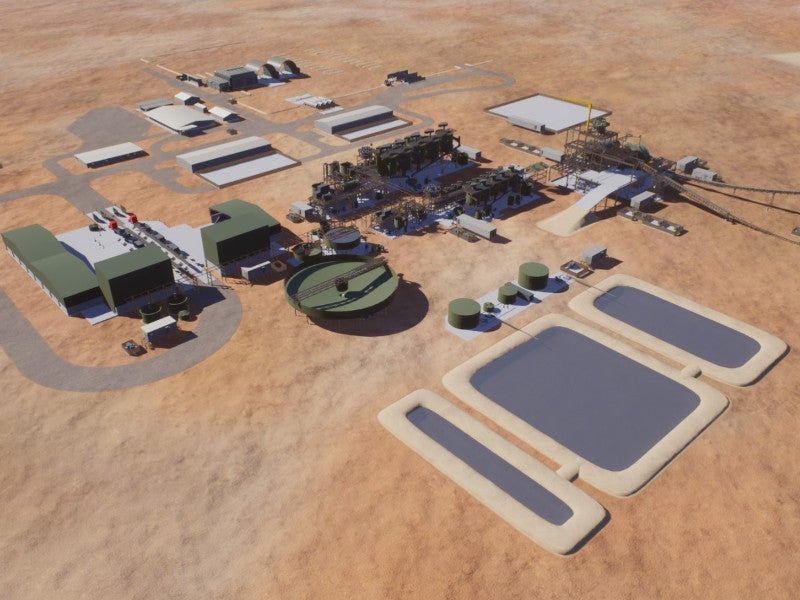

Bel Air construction

Early construction works of Bel Air include the construction of quarry, mine camp, and other auxiliary services, while the main works include the development of the export facility.

Construction works on the foundations of the causeway and breakwater were completed by December 2017. Work on the barge loading facility, haul roads and accommodation camp is currently ongoing.

Infrastructure facilities

Onshore infrastructure facilities at Bel Air include a self-contained camp and operations centre, water wellfields, and dedicated communications and internet connection. Power supply for the mine will be provided by on-site diesel generators.

Access to the mine is via the 25km-long Bel Air Road connecting the RN3 Highway from Conakry to Boke. A new access road is proposed to be constructed to connect the mine with the export facility.

Financing

Alufer Mining received a $205m investment from a consortium of international investors including the Africa Finance Corporation (AFC), Orion Mine Finance and Resource Capital Funds for developing the Bel Air bauxite mine.

Contractors involved

Alufer Mining awarded a five-year contract to Mitsui O.S.K. Lines in December 2017 for transporting DSO bauxite from Bel Air. Nurizon carried out the pre-feasibility study for the mine development.

Insuco was involved in the preparation of the environmental and social impact assessment report for the mine.