Apps have the potential to completely transform mining operations; in the near-term allowing companies to track their resources at any location at any time, while in the long-view, supporting the implementation of autonomous mining, the industry’s undisputed future.

One company working to bridge the gap between the industry and app technology is Perth-based MiPlan, which offers a range of tools for field data collection, fleet management, production management and reporting.

MiPlan was recently acquired by Hexagon Mining – a software firm that develops integrated planning, operations and safety solutions – in a move the companies hope will help operators make better sense of their data, resulting in safer, more productive mines.

“The acquisition of MiPlan aligns perfectly with Hexagon Mining’s strategy of providing solutions that are easy to use, easy to implement, and easy to support,” said Hexagon spokesperson Neville Judd. “Applied to Hexagon Mining’s suite of technologies for planning, operations and safety, MiPlan solutions will empower customers to act, not react, on real-time data at any stage of the mining value chain, no matter their location.”

See Also:

Elly Earls caught up with MiPlan co-founder and project director Louise Daw to find out how apps have already changed the mining sector, and what we can expect in the future.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataElly Earls: Why are your mobile apps so suitable for the mining industry?

Louise Daw: Mines are typically remote and outside of network range, but apps can connect the site through a local network so that people can understand what all of their resources are doing in real-time.

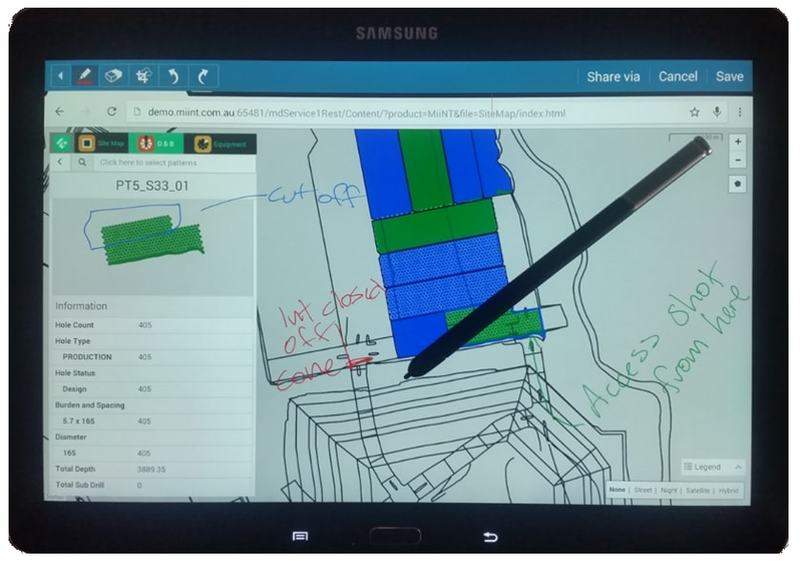

Apps can also help remove the need for paper on site. Regardless of whether an operation has a fleet management system (FMS) or not, there is an enormous volume of paper work and follow on data entry effort required – things like timesheets, pre starts, safety hazards and blast patterns.

An operator might go out into the field to do a job and have six or seven pieces of paper with him but by the time it’s been written on paper and somebody’s entered it into a local system, it’s at least 24 to 48 hours old.

It’s an expensive task for a mine to base decisions on old data. Apps give you the ability to know where your resources are at any time and that’s huge for safety and productivity in the mine.

EE: How big a role are apps playing in the mining industry at present?

LD: The mindset of mining companies is starting to change. We are finding now that people are Googling mining apps a lot more and that’s only started to change in the last 18 months. There is a new generation coming through that is embracing the concept of saying ‘There should be an app that exists for this problem’.

However, from what we’ve seen, apps are typically created for a specific function, meaning mine sites trying to adopt apps may be able to remove the paper, but they still end up with lots of disparate data sets and someone is having to manually take those datasets and combine them so that they’re useful.

Our mobile solutions cover the full mine lifecycle, including manual activities meaning an operation can maintain and manage all the data collected from the various apps in a single platform. For apps to succeed at mine sites, this must be the way forward.

EE: What key benefits will Hexagon’s acquisition of MiPlan bring to both companies’ clients?

LD: Apps are only as good as the systems they are connected to. The mobile apps MiPlan has developed are dependent on high-quality design and scheduling information. The Hexagon acquisition means design applications and apps can be linked directly allowing changes to the plan to be communicated instantly throughout the business.

Linking a client’s design package to the apps has allowed clients to reduce the timeframe between drill and blast activities from four days to under a day. This was achieved by engineers gaining real time access to field conditions and re-designing blasts based on the information. The redesigns can then be published instantly to the team on the ground [which] can immediately action the changes. There is no lag between receiving and entering data form paper to the re-design.

In regards to managing the fleet, the union allows the businesses to take the best of both fleet offerings and combine them to provide clients with a comprehensive offering, which can be deployed rapidly, is easy to use and simple to maintain. For example, MiPlan had been interested in finding a way to connect to vehicle health systems to collect additional metrics and Hexagon already has this technology, so we have a huge leap forward in this space.

We have also been interested in providing solutions with a low or no network cost setup. Hexagon already has a peer to peer network solution which is in use across 25,000 units around the world meaning another leap forward in the capability of our apps and our overall platform.

EE: How do you anticipate MiPlan’s apps will evolve together with Hexagon over the coming years?

LD: The solutions will merge into a single LiveMine solution, which can scale from quarries right through to the largest Tier 1 mine sites. The focus of the merged solution will continue to ensure rapid deployment, ease of use and simple maintenance. [We anticipate being able to offer] peer-to-peer networking for open-pit and underground mining, machine health management and live production analysis. It’s really, really exciting what we’re going to be capable of doing in the short and long term.

EE: In five years’ time, how big a role will apps play in the mining sector? What will they be capable of?

LD: I think that everybody who’s working in the software industry in mining knows that the real focuses for the future are predictive maintenance, fleet optimisation and, the big one, autonomous mining. Apps will play an instrumental role in progressing those three areas.

Apps basically collect and present data to the right people in a timely manner so they’re able to start making proactive decisions. As the scope of the apps increase and we’re able to interface with additional planning tools from Hexagon, employers are going to be further empowered with having real-time planning and information updates, so they can ensure that there is continuous business improvement and optimisation.

Moreover, because you’re going to have apps and sensors available in nearly every single activity involved in the mining lifecycle, you can take all of that data and blend it into valuable information on which to base predictive analysis, machine health management and also improved fleet optimisation.

Apps that create and maintain their own peer-to-peer network and can be connected to the machine is the first step towards a realistic vehicle intervention model, the gateway to autonomous mining. That’s where it’s going and that’s where we want to take the apps.