Ohio Automation specializes in mine planning, ventilation and water software for underground mines

Our integrated computer-aided mine planning software (ICAMPS) products run on the AutoCAD platform (2010 and above) so that you have full accessibility to all functions and commands.

Underground mining software

ICAMPS is a complete underground mining software solution. We have MineSimU for mine planning that produces timing maps, tonnage reports, and much more. MineVent and MineVent 3D for mine ventilation software. MineWater to simulate water flow systems. Finally MineFire for mine ventilation in real-time to simulate what happens if a fire occurs or even if other changes occur while simulation.

High-performance mine ventilation software

Our popular MineVent and MineVent 3D mining ventilation software modules simulate the airflows (cfm) through the airways and pressures (inches H2O) at the nodes.

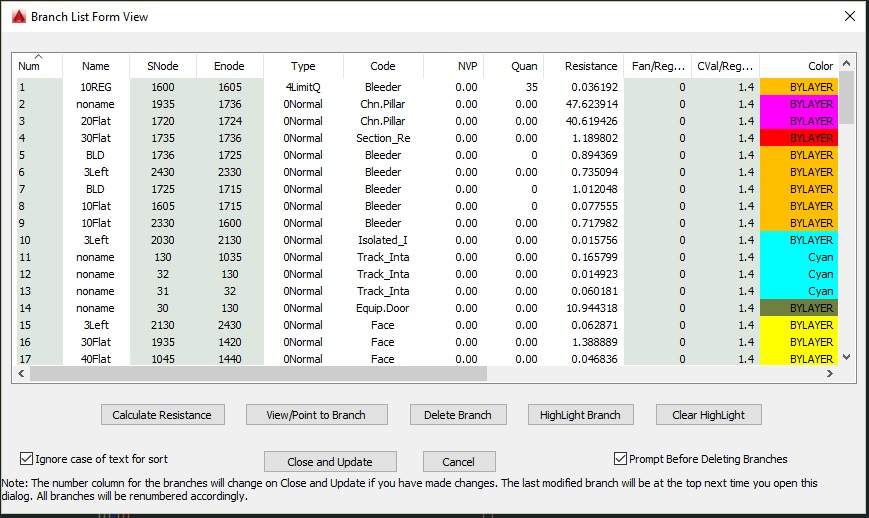

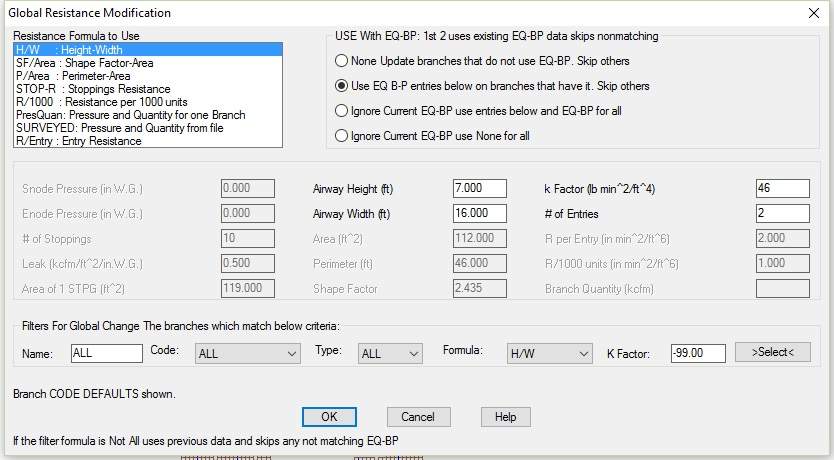

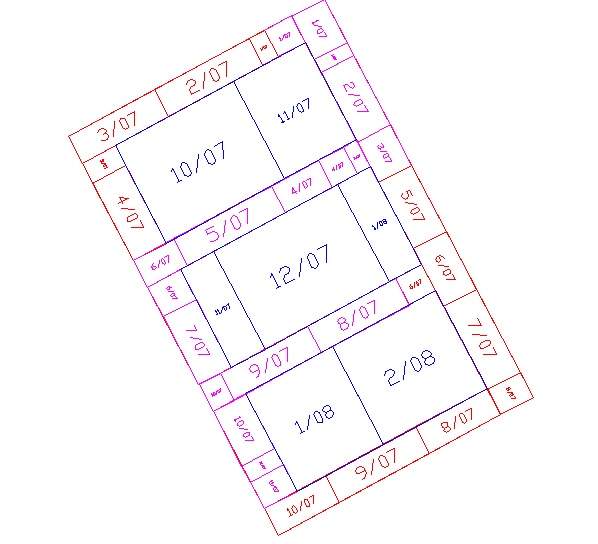

Realistic mine maps shows how user-defined branch codes such as intake, return or leak can have different colours and abide on different layers. It has many modification and output features. Modification features include moving and stretching branches, globally changing the branch parameters such as resistances, editing branches graphically and in list format, export to spreadsheet and more.

Ventilation simulation software using Hardy Cross and Gradient

MineVent uses an enhanced version of the Hardy Cross Method and a second more robust engine called the Gradient Method for calculations. The programme can use the actual mine map to draw the ventilation network and then use the actual branch lengths to calculate resistances using one of ten formulas or entering the resistance by hand. It has special formulas for leakage branches and regulators and calculates the regulator openings.

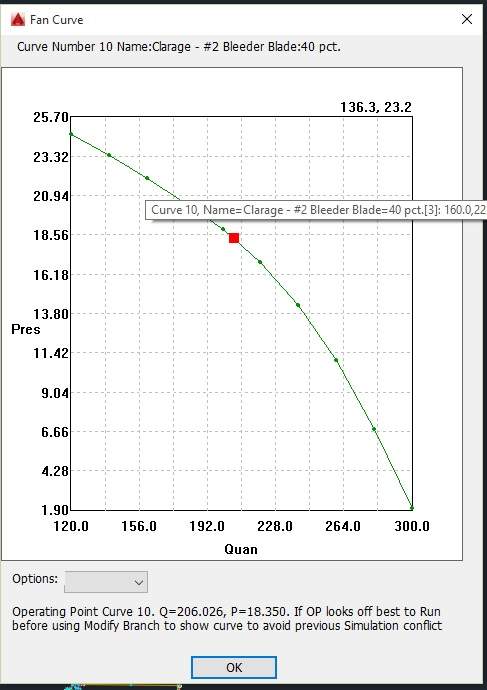

A number of the more popular output features are List Compare, which compares the results of the last two runs to see what effects a change has on the ventilation network, along with listing quantities, pressures, pressure drops, negative quantities, regulators and branch cost. The output includes the fan cost. You can also graphically see fan curves and the operating point.

Graphically, you can draw the quantities and pressures on the network at any size, draw gas flow percentage, and colour the network by parameters. MineVent supports Imperial and SI units.

Ventilation design software for fires

MineFire 3D runs inside of the AutoCAD programme, and has an easy-to-use graphical user interface in comparison to the former US Bureau of Mines MFIRE version 2.20 expanded upon and improved by National Institute for Occupational Safety and Health (NIOSH) to include real-time modifications, now called MFIRE 3.0.

The difference between MineVent and MineFire is that it requires more input, has more output, runs in real-time so that you can make changes while it is running or in a timetable before running and has three phases: steady state, non-steady state and the quasi-equilibrium. In theory, the Steady State should yield results similar to MineVent. However, MineVent is much better for Steady State ventilation and likely to be more accurate.

MineFire can also be used to simulate ventilation networks changes such as resistance change, temperature and fan changes in real-time.

Underground mine scheduling and planning software

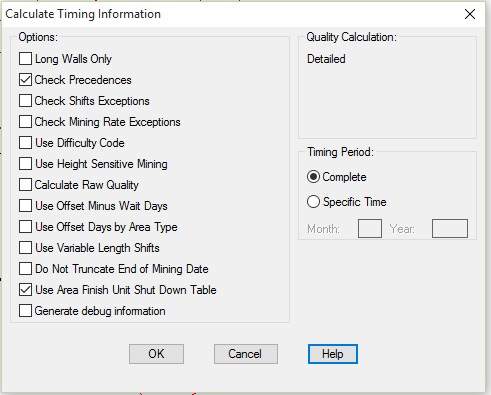

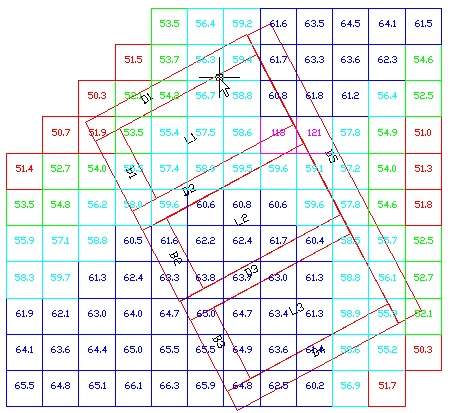

Our MineSimU underground mine planning and scheduling software creates many different detailed tonnage reports, timing maps, royalty reports and much more. Monthly and daily scheduling are also available.

It comprises features for longwall moves, area finish and machine shutdown, graphical calendar creation with automatic creation and holidays or certain days of the week off, shift exceptions, mining rate exceptions and is a complete mine planning simulation software package. Geological and quality data in grid format changes are easy to implement.

Water flow simulation software

MineWater is used to simulate the flow of water through complex piping systems. It is similar to MineVent, has some of the same menu options and is water instead of air.

It is also similar to MineFire as it works over time as water flows through the mine so you can step through to see if a tank is empty, or what the water flow (gpm) and pressures are in each pipe and node as you go through pre-determined time steps.

The nodes are different in that they can be either a junction where pipes join or characteristics change, a source which is an inflow into the system, or a sump storage tank.