FAMUR Group is a producer and supplier of machinery and equipment used in the mining industry all over the world. The main areas of our activity are underground and open-pit mining, transport, bulk material handling, and the power industry.

More than 100 years of our experience and advanced engineering know-how allow us to develop high-performance and reliable products, enabling to complete the most complex mining and energy projects. We specialize in longwall, roadheading, underground and surface transport systems, open-pit mining machines as well as equipment for mass transport and bulk material handling.

Machinery and equipment for underground mining

FAMUR focuses on technologically advanced and highly efficient automated longwall systems equipped with control systems, monitoring system of machine states, processes and technical systems, along with IT support, which significantly improve safety and efficiency.

FAMUR is a leading manufacturer of a wide range of roadheaders and equipment used in the underground mining. Our offer includes roadheaders, dinting loaders and loaders, bolting and drilling rigs, as well as fixed drilling rigs.

FAMUR specializes in designing and manufacturing a range of equipment for continuous transport and reloading of various types of bulk materials used in underground mines, such as cable-driven floor railways, diesel engine suspended monorails, diesel engine floor railways, diesel track locomotives and mechanical winches, as well as complete equipment for railways to transport personnel and materials.

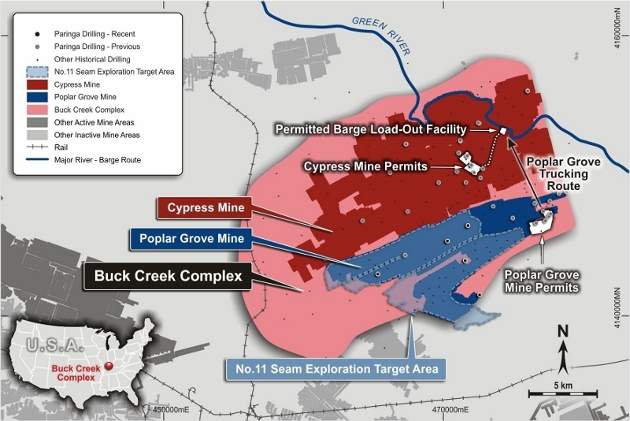

Machinery and equipment for open-pit mining

A significant area of FAMUR activity is focused on machinery and equipment used in open-pit mines. We design and manufacture bucket-wheel excavators, chain-and-bucket excavators, stackers, caterpillar transport vehicles and conveyors.

Continuous transport systems

Transport systems by FAMUR are designed for continuous haulage and transport of materials as well as people transportation. Our machines successfully operate in underground and open-pit mines, sea and river ports, reloading centres and storage yards. They are used in internal transport and in large scale earthworks. Our products within this group are: complete technological systems for continuous transport of bulk materials, conveyors (belt conveyors – including man-riding conveyors, bucket conveyors, drug conveyors and screw conveyors), complete material and man transport systems such as suspended monorail or floor rail systems with diesel-powered locomotives, rope winches, track locomotives and complete rail routes.

Industrial systems

FAMUR provides comprehensive IT solutions for industry and mining sector. Our offer includes power supply and control systems for mining machinery. We design and implement software for monitoring, control and reporting of technological processes. We have developed e-mine solutions designed for data aggregation and transmission, as well as diagnostic systems. FAMUR specializes in the manufacture of explosion-proof electronics, explosion-proof electrical equipment boxes for mining machinery and frequency converters operating in potentially explosive areas.

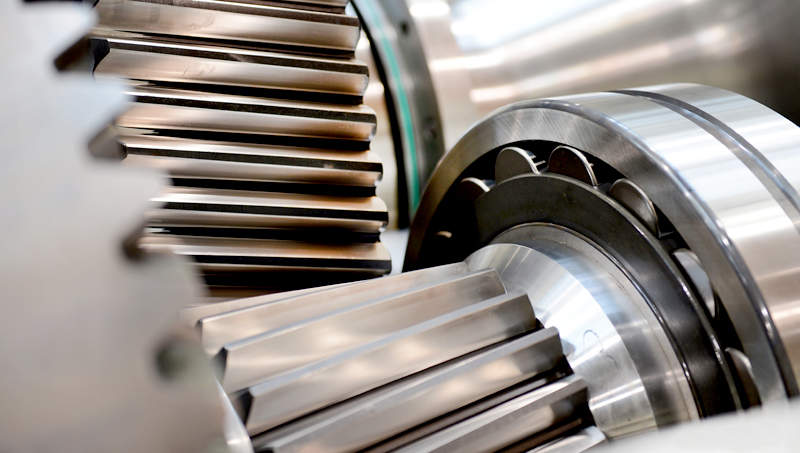

We design and deliver industrial-class gearboxes to many market segments, in particular to underground and open-pit mining, cargo handling machines and gantry cranes, as well as bulk materials transportation machines. Our gearboxes successfully and reliably operate in cutting drums, scraper and belt conveyors and other industrial processes and technologies.

Technologies and services for mining

FAMUR specializes in comprehensive design and construction of mineral processing and beneficiation plants, construction and equipment of mine shaft hoists, as well as comprehensive delivery of complete technological systems including concept development, design preparation, construction, start-up, commissioning and overall process supervision.

FAMUR provides process and construction designs for mining and power industry as well as design and delivery of machines and equipment for open-pit mining.

Solid as always, stronger than ever

Consistent combination of experience and potential of the largest Polish mining brands allowed FAMUR Group to build a comprehensive portfolio. We continue the tradition of companies such as Famak, Glinik, Fazos, Remag, Pioma, Nowomag, Elgór+Zamet and Pemug. Thanks to integration with Kopex, which had been our main competitor, we have become a national leader, ready to face global challenges stronger than ever. FAMUR Group is part of TDJ SA.

To find out more about FAMUR products, please contact us using the details or form below.